In Short

Supplier compliance in strata means pre-qualifying vendors by risk tier, validating licences and insurance, enforcing on-site controls (inductions, permits, SWMS), monitoring performance with KPIs, and embedding obligations in contracts and work orders.

Done well, it reduces incidents, speeds approvals and keeps audits clean.

- Pre-qualify by risk (low/medium/high) with minimum evidence per tier.

- Store documents in one place with auto-expiry blocks.

- Make it real on site: induction, job-specific SWMS, permits, photo proof.

- Track KPIs (renewals, response, first-time-fix, incidents) and audit quarterly.

- Bake rules into contracts: service levels, remedies, building rules.

What is Supplier Compliance in Strata?

Supplier compliance is the practical, day-to-day system that ensures every tradie and contractor who touches common property is legally qualified, fully insured and working to your building’s safety and conduct rules, before they’re booked, during the job and after it’s closed out.

Think of it as a simple chain: verify the right people, verify the right documents, verify the right controls on site, and verify the right behaviours over time.

For strata managers, it’s less about red tape and more about predictable outcomes: fewer incidents, faster approvals, less resident disruption, lower callback rates and clean evidence for insurers or regulators. When supplier compliance is strong, committee conversations are calmer because decisions ride on facts, not feelings.

Why Supplier Compliance Matters?

Strata work is unique: mixed risk across many small jobs, frequent access to resident areas, and high scrutiny from committees. Without supplier compliance, small oversights snowball, an expired Certificate of Currency becomes a claim problem, a generic SWMS leads to a near miss on a roof, a subcontractor arrives un-inducted and blocks lifts at peak hours.

These moments erode trust, chew up budget and generate complaints that take longer to resolve than the job itself. With a clear, friendly compliance system, you reduce those frictions dramatically and keep your time focused on approvals and outcomes, not inbox archaeology.

1. Risk-Based Pre-Qualification that Scales

Not all jobs carry the same chance or consequence of harm. A single fall from a roof or an electrical incident can trigger injury, insurance headaches and reputational damage.

What goes wrong when it’s missing

Everyone gets the same checklist. Low-risk suppliers drag their feet, routine work stalls, and managers resort to ad-hoc approvals. Meanwhile, high-risk contractors glide through with the bare minimum, show up without site-ready controls, and leave you exposed if something goes wrong.

Disputes become harder to resolve because your standard wasn’t calibrated to risk in the first place.

Why is it important

Tiering prevents two common failure modes: over-burdening low-risk suppliers with bureaucracy, which slows maintenance and under-scrutinising high-risk work, which drives incidents.

Group suppliers into risk tiers and require evidence that matches the risk.

Low-risk trades (e.g., routine cleaning or basic handyman tasks) deserve a light, fast path, proof of identity, licences and insurance. Medium-risk trades (typical plumbing, door hardware, minor roofing inspections) need fuller verification: workers’ comp, trade tickets, scope-appropriate licences. High-risk trades: anything at heights, live electrical, significant roofing, glazing or hot works, must meet higher bars: stronger insurance limits, job-specific capability (SWMS competency), evidence of supervision and incident reporting.

How it works

- Map trades to Low / Medium / High.

- Define the minimum doc set per tier (licences, CoCs, workers’ comp, tickets; add SWMS capability, QA and references for High).

- Validate entity names and limits; approve for 12 months.

- Block bookings if core documents are missing or expired.

2. One Source of Truth for Documents & Expiries

Most compliance failures aren’t dramatic; they’re quiet lapses: an insurance renewal missed in someone’s inbox, a licence update trapped on a desktop, a name mismatch discovered during a claim.

What goes wrong when it’s missing

Evidence sprawls across email threads, shared drives and staff PCs. People leave, and knowledge leaves with them. You waste time chasing PDFs. Jobs get booked with lapsed cover because the spreadsheet didn’t update. If a committee or insurer asks for proof, you scramble to reconstruct history instead of exporting it in seconds.

Why is it important

Centralisation kills those failure points. It also gives you a live picture of readiness: who can attend which building right now.

Keep all supplier evidence in a single system that labels each document by supplier, trade and site, tracks expiry dates, and sends automatic reminders.

On the day a document expires, the system hard-blocks bookings until a valid replacement is uploaded and verified.

Validation is simple but deliberate: confirm the policy holder’s legal entity matches the contract and invoice name; check insurance limits against building risk (e.g., tall buildings or major plant may justify higher public liability); ensure the licence class covers the job’s scope. Provide committees with status-only views (approved/pending/expired) and give building managers direct access to the documents they actually need on the ground.

Make it practical

- Store by supplier → trade → site, with versioning and expiry dates.

- Auto-emails at T-30/14/7; hard block on day 0.

- Validate policy holder vs ABN, limits vs building risk, licence scope vs job.

- Give committees status-only visibility; give building managers the docs they need.

3. Make Compliance Real on Site

Most harm occurs at the point of work, not in the office.

A polite, two-minute induction and a site-specific SWMS do more to prevent injuries, fires and outages than any policy document. They also minimise resident impact by planning around lifts, quiet hours and access peculiarities that only surface on site.

What goes wrong when it’s missing

Crew arrives guessing the rules, block lifts at school-run time, drill during quiet hours, or access roofs without anchors. Generic SWMS ignore your building’s realities, leading to near misses and corrective re-visits. Complaints rise, jobs slow, and your day disappears into mediation. If an incident occurs, you lack evidence that controls were considered, agreed and used.

Why is it important

This translates paperwork into on-site habits. Use a short pre-start induction that covers access rules, noise windows, lift protection, hazards, emergency contacts and clean-up expectations. For high-risk work, require a job-specific SWMS (or JSA) that reflects your building: roof edges, anchor points, plant rooms, switchboards, confined spaces and access routes. Issue permits that match the task: hot works (with a named fire watch and cool-down), roof access (anchors/edges), and LOTO for electrical isolation. During and after the job, capture time-stamped photos showing controls in place and the site restored. These aren’t box-ticking exercises; they’re the last step between good intentions and safe outcomes.

On the day

- Induct: access, noise windows, lift protection, hazards, emergency contacts.

- Check: site-specific SWMS aligns with the building and task.

- Permit: hot works (with fire watch), roof access (anchors/edges), LOTO for electrical.

- Evidence: time-stamped photos, controls in place, clean-up done, access relocked.

4. Measure What Matters

What gets measured gets better. KPIs expose patterns early: crews that struggle with first-time fixes, trades that habitually miss renewals, and sites that generate recurring complaints. With data, you can praise, coach or replace with confidence, and you can explain those decisions to committees without drama.

What goes wrong when it’s missing

Procurement becomes memory-based. The loudest voice in the room picks the next vendor. Underperformers quietly stay on rotation because “they were fine last time,” even if the numbers say otherwise. Minor non-conformances repeat until they become incidents. Residents lose patience; committees lose trust.

Why is it important

Tracking a handful of KPIs helps predict smooth jobs, run regular audits, and use scorecards to coach suppliers.

Numbers to watch: on-time document renewals (a leading indicator of attention to detail), emergency response time, first-time-fix rate, callback rate, SWMS adequacy (were controls job- and site-specific?) and incident/near-miss frequency. Share these metrics openly with suppliers so expectations are transparent. Schedule quarterly document audits and random site checks; after any non-conformance, issue corrective actions with deadlines. Fold resident and committee feedback into the rating so the score reflects safety and service.

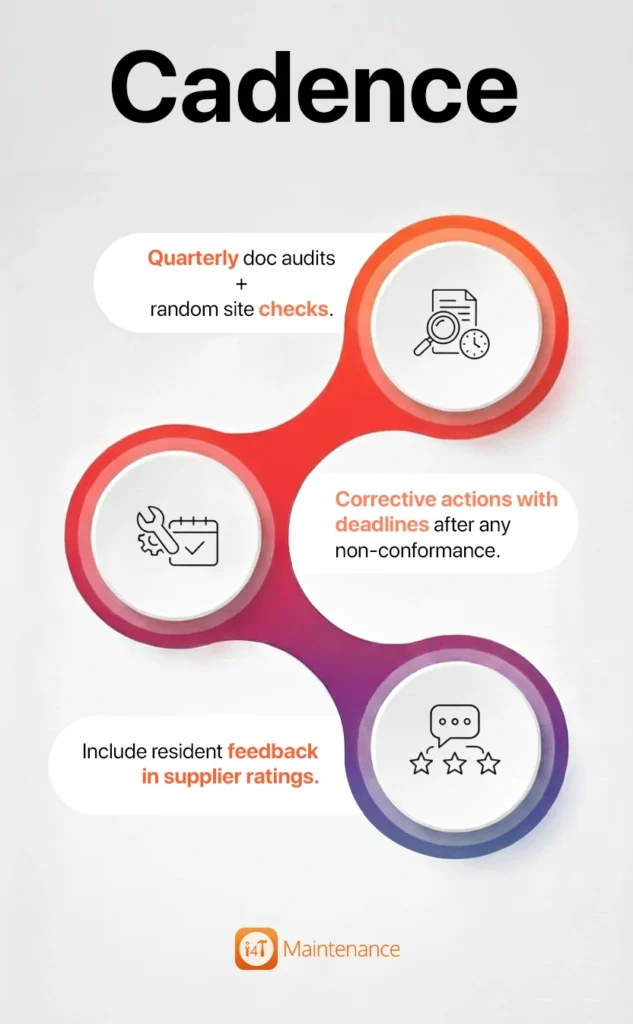

Cadence

- Quarterly doc audits + random site checks.

- Corrective actions with deadlines after any non-conformance.

- Include resident feedback in supplier ratings.

5. Bake Compliance into Contracts & Work Orders

Clarity prevents conflict. When terms are specific: hours, lift protection, waste removal, key custody, resident notices, crews arrive aligned, and disputes shrink to edge cases. If a breach occurs, you have a pre-agreed escalation path and remedies, not a fresh argument.

What goes wrong when it’s missing

Assumptions multiply. Contractors say, “We’ve always done it this way,” residents say, “We were never told,” and committees say, “Who approved this?” Payment stalls, tempers rise, and your inbox fills with lengthy threads because there was no shared rule book.

Why is it important

When you put obligations and consequences in plain-English contracts and work orders, there’s no debate later.

Contracts should set minimum insurance limits, licensing warranties, adherence to safety laws and your building rules, incident reporting timelines, privacy and data handling, and your right to audit. If a head contractor uses subcontractors, bind them to the same standards and hold the head contractor responsible for their compliance. Work orders should state service levels and documentation due-by points, with payment milestones tied to compliance deliverables.

Include

- Mandatory clauses (insurance limits, licensing warranties, safety, privacy, incident reporting, right to audit).

- Service levels (emergency/routine response, rectification times, doc due-by points).

- Remedies (suspend, withhold, rework at cost, terminate for repeats).

- Building rules (hours, noise, waste, lift protection, key custody, resident notices).

- Template pack: Master agreement + trade addenda + job order terms + induction/permits.

Make compliance a habit, not a hurdle

In strata, the fastest path to safe, low-stress maintenance is a sequence you can repeat without thinking: risk-tier the supplier, confirm the evidence, set the on-site controls, watch the KPIs and anchor it all in clear contracts.

These Best Practices for Supplier Compliance aren’t paperwork for paperwork’s sake; they are the scaffolding that keeps residents safe, budgets steady and meetings short.

This matters now more than ever, because buildings are busier, trades are stretched, and committees expect transparency. When compliance is ad-hoc, managers cop the heat for delays and defects they didn’t cause. When compliance is systemised, you spend less time firefighting and more time delivering, approvals are faster because standards are known, disputes are rarer because expectations are written, and audits are easier because the evidence is already organised.

If you want the whole flow in one place, use i4T Maintenance – Maintenance Management Software. It brings supplier pre-qualification forms, a document vault with auto-expiries, KPIs and contract terms embedded into every work order, so you manage buildings, not email attachments.

FAQs

Match risk. Many schemes use $10-20 million public liability as a baseline; raise limits for high-risk works. Always match the policy holder to the legal entity and sight the Certificate of Currency.

For high-risk tasks: heights, live electrical, confined spaces, asbestos, hot works. It must be job- and site-specific and reviewed before attendance.

Yes, permit a capped make-safe, but core docs (licence, insurance) must exist, and the SWMS/permit must follow quickly. Enforce tight follow-up.

Keep for the life of the asset plus several years, or as your insurer/regulator advises. Store by supplier, job and asset for easy retrieval.

On-time renewals, emergency response, first-time-fix, callbacks, SWMS adequacy, incidents/near-misses. Roll into a simple scorecard.

Quarterly doc checks plus random site audits; focused reviews after incidents.

A central system with auto-reminders and booking blocks for expired docs; suppliers self-upload; managers validate with an audit trail.